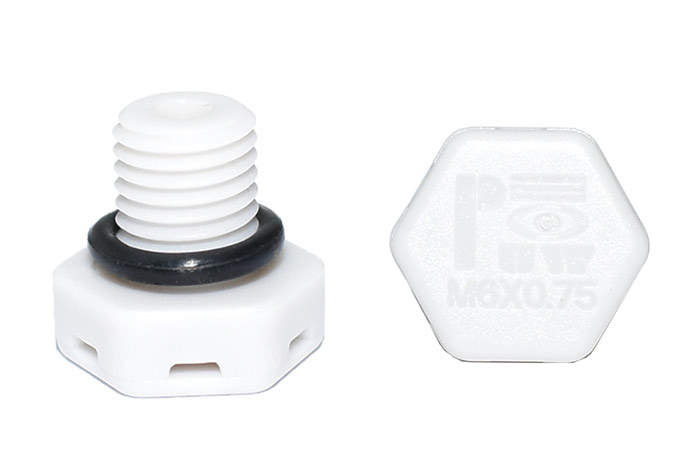

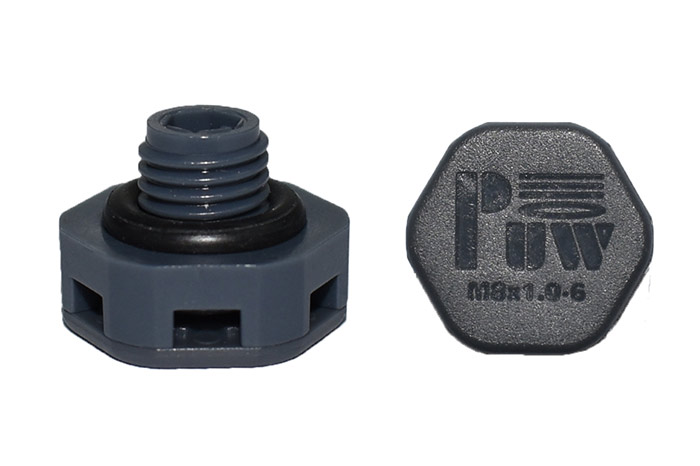

PUW Plastic Breather Valves are precision-engineered for modern battery systems, especially lithium-ion battery packs used in electric vehicles (EVs), energy storage systems, and portable electronics. These valves help manage internal pressure changes while providing waterproof, dustproof, and chemical-resistant protection, thereby ensuring battery safety, reliability, and performance over time.

| Product model | PUWKK8.5-4.5-17 |

|

|

| product type | Plastic vent valve | Body material | PC |

| Air permeability ml/ min@7kPa | ≥1800 | Degree of protection | IP67 |

| Air permeability ml/ min@7kPa | 250-750 | Degree of protection | IP68/IP6K9K |

| Thread length | / | Installation mode | / |

| colour | black | temperature range | -40°C~125℃ |

| Installation torque | / | Flame retardant grade | UL94-V0 |

| Application | LED outdoor lighting industry

Automobile manufacturing industry

Solar photovoltaic industry

Electronic and electrical industry

Communication equipment industry

Security equipment industry |

Why Battery Packs Need Breather Valves

As battery packs operate and charge/discharge, internal heat causes air expansion, increasing internal pressure. Without venting, this may lead to:

Housing deformation or rupture

Moisture ingress and condensation

Electrochemical degradation

Short circuits and safety risks

PUW’s breather valves offer automatic pressure equalization while keeping water, dust, oil, and gases out. This is crucial for:

High Weather Resistance

Designed to withstand UV rays, rain, temperature shifts, and harsh outdoor conditions. Suitable for both indoor and outdoor battery systems.

Excellent Structural Strength

Made from durable plastics with reinforced construction. Vibration-proof, impact-resistant — ideal for electric vehicles and industrial batteries.

Long Service Life

Low-maintenance design with high-performance membranes ensures stable performance over time, even in demanding environments.

Customizable Options

Support for various materials (PA66, PC, PP, etc.), colors, thread types, vent sizes, and membrane characteristics (hydrophobic/oleophobic). Logo and packaging can also be customized for OEM/ODM projects.

Working Principle – Intelligent Venting, Superior Protection

PUW breather valves integrate a microporous PTFE membrane inside a protective plastic housing. This structure enables:

Air pressure balancing: Allows air and gas to flow in/out

Water & dust barrier: Blocks contaminants (IP67–IP68 rated)

Thermal adaptation: Protects against heat-induced swelling or shrinkage

Chemical resistance: Durable in acid/alkali environments often present in batteries

The result is a more reliable, longer-lasting, and safer battery pack.

Application Fields

PUW plastic breather valves are widely used in battery pack enclosures for:

Electric Vehicles (EVs)

Battery modules in electric cars, e-bikes, scooters. Maintain enclosure stability under high-speed, high-temp conditions.

Energy Storage Systems (ESS)

Stationary lithium battery storage, power walls, solar backup systems. Reduce condensation risk and increase safety.

Consumer Electronics

Power banks, laptops, tablets. Keep moisture out and prolong battery health.

Industrial Batteries

AGVs, forklifts, backup power units. Withstand industrial-level vibration and temperature changes.

Outdoor Battery Boxes

Telecom batteries, surveillance power systems. Prevent fogging and water damage in exposed environments.

Why Choose PUW Battery Breather Valves?

10+ years of experience in waterproof venting

International standard testing and certifications

Strong R&D support for customized requirements

Small MOQ, fast delivery, and global logistics

Professional team for technical and after-sales support

FAQs

Q1: Can the valve be used in high-voltage EV battery packs?

Yes. Our breather valves are designed for both low-voltage and high-voltage lithium battery applications.

Q2: Will the membrane get clogged over time?

No. Our membranes are oleophobic and anti-clogging, ensuring consistent airflow while blocking contaminants.

Q3: Can I request a custom design?

Yes. We support full customization including vent shape, installation method, membrane type, and branding.

Q4: Do you offer samples for testing?

Yes, free or low-cost samples are available for compatibility testing.