PUW Plastic Air Vents are specially engineered to protect sensitive electronic equipment from environmental challenges such as water, dust, temperature fluctuations, and chemical exposure. Designed for both performance and flexibility, our air vents deliver high weather resistance, robust structural strength, and a long service life, making them the ideal choice for industries demanding reliable enclosure protection.

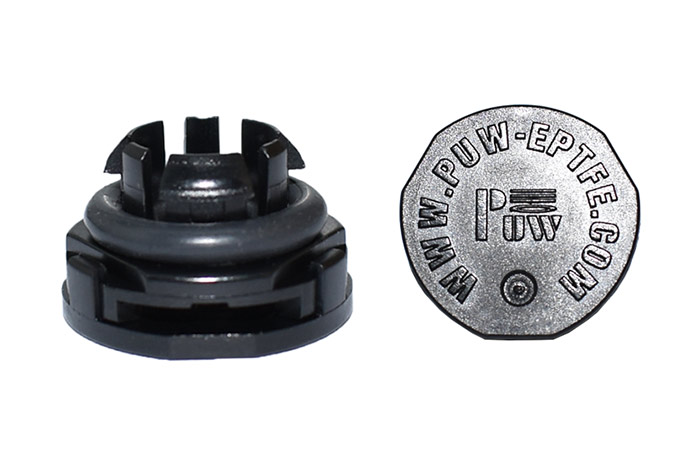

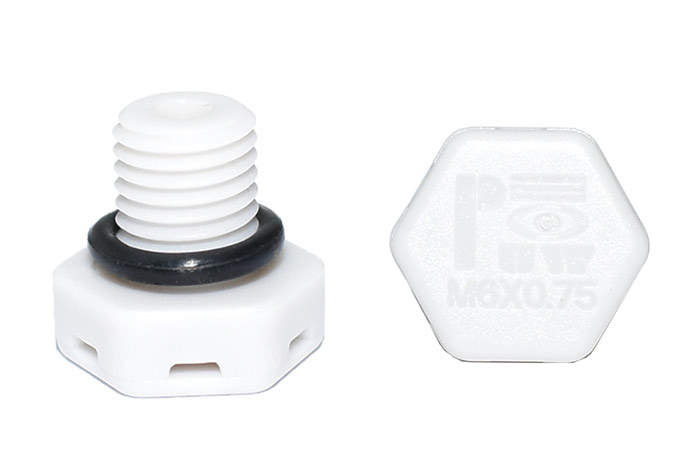

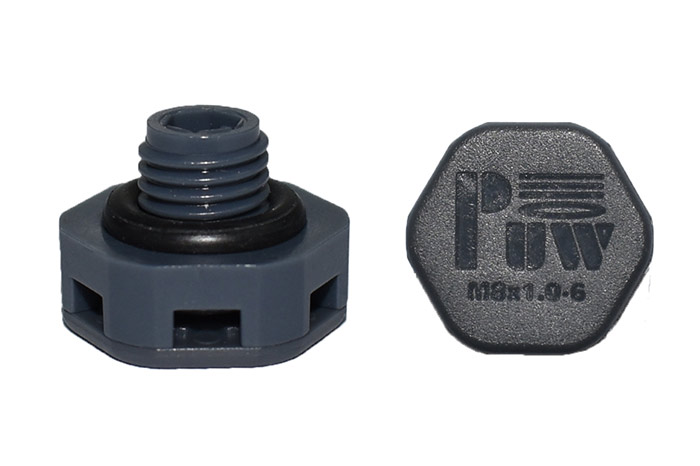

| Product model | PUWKK8.5-3.6 |

|

|

| product type | Plastic vent valve | Body material | PC |

| Air permeability ml/ min@7kPa | 300-800 | Degree of protection | IP67 |

| Air permeability ml/ min@7kPa | 100-350 | Degree of protection | IP68/IP6K9K |

| Thread length | / | Installation mode | / |

| colour | black/darkgrey/off-white | temperature range | -40°C~115℃ |

| Installation torque | / | Flame retardant grade | UL94-V0 |

| Application | LED outdoor lighting industry

Automobile manufacturing industry

Solar photovoltaic industry

Electronic and electrical industry

Communication equipment industry

Security equipment industry |

How It Works — The Venting Principle

Electronic enclosures often experience internal pressure changes due to temperature variation or altitude shift. Without proper venting, this pressure difference can lead to:

Deformation of the housing

Seal failure and water/dust ingress

Shortened lifespan of internal components

PUW’s plastic air vents use a microporous PTFE membrane that allows air and gases to pass freely while blocking water, dust, oil, and contaminants. This pressure equalization function keeps the enclosure balanced, dry, and protected — ensuring optimal operation of electronic components.

Product Features

High Weather Resistance

Excellent performance in extreme outdoor environments. UV resistant, anti-aging, and stable under long-term exposure to sun, rain, and wind.

High Structural Strength

Reinforced plastic housing resists impact, vibration, and deformation. Suitable for high-vibration applications such as automotive or industrial equipment.

Extended Service Life

Durable materials and advanced sealing ensure long-term use with minimal maintenance. Reduced failure rates improve device reliability.

Customizable Materials & Models

Choose from various plastic materials, thread types, vent diameters, and membrane grades. OEM/ODM customization supported, including logo, structure, color, airflow rate, and packaging.

Applications

PUW Plastic Air Vents are trusted across multiple industries where environmental sealing and pressure equalization are critical:

Automotive Electronics

Control modules, battery systems, headlights, ADAS cameras. Protect against pressure buildup, moisture, and road chemicals.

Telecommunication Equipment

Outdoor base stations, antennas, routers, signal amplifiers. Maintain stable internal pressure while preventing condensation.

Smart Home Devices

Outdoor security cameras, doorbells, smart locks. Enhanced reliability in all-weather conditions.

LED Lighting Systems

Street lights, tunnel lights, solar-powered lights. Venting improves heat dissipation and prevents lens fogging.

Industrial Control Boxes

Sensor housings, junction boxes, power inverters. Prevent corrosion and overheating in harsh working environments.

Surveillance & Monitoring Systems

Enclosures for outdoor CCTV, wildlife cameras, environmental sensors. Critical for clear imaging and uninterrupted monitoring.

Why Choose PUW

Over 10 Years in Waterproof & Venting Technology

Strict Quality Control with International Certifications

Fast Global Delivery and Flexible MOQ

Responsive Service & Engineering Support for Custom Projects

FAQ

1. What is the main function of a plastic air vent in electronic enclosures?

The primary function is to equalize internal and external pressure while preventing water, dust, and other contaminants from entering the enclosure. This helps protect internal electronic components and extend their service life.

2. Is the plastic air vent waterproof?

Yes. Our plastic air vents are equipped with a microporous PTFE membrane and are rated up to IP68, ensuring effective waterproof and dustproof performance.

3. Can I customize the air vent to fit my enclosure design?

Absolutely. We offer full OEM/ODM customization services, including vent size, color, structure, mounting style (threaded, snap-in, adhesive), airflow rate, and branding/logo.

4. What materials are used in PUW plastic air vents?

We use UV-resistant plastic for the housing and hydrophobic or oleophobic PTFE membranes for the venting layer. Material options can be adjusted based on your environmental or application needs.

5. How long is the typical service life of the vent?

Our vents are designed for long-term durability and can last for many years, even under extreme weather conditions such as high UV exposure, temperature fluctuations, and corrosive environments.